-

Labeling Machine

- Female

- Gadsden

- United States

- Share on Facebook MySpace Tweet

- Blog Posts

- Discussions

- Events

- Groups

- Photos

- Photo Albums

- Videos

RSS

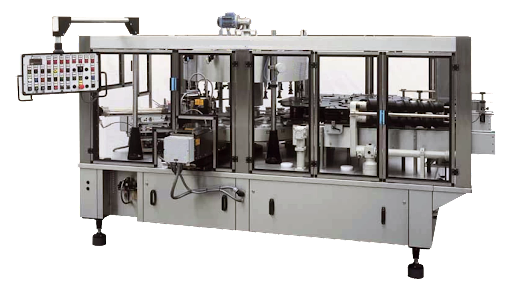

Best Bottle Labeling Machines for Beverage, Cosmetic, and Pharmaceutical Packaging

Why It’s Critical to Pick the Right Labeling Machine

In packaging, the right labeling machine can make all the difference. It determines how efficiently your production line runs, your labeling accuracy, and how your product looks on the shelf. For companies in the beverage, cosmetic, and pharmaceutical industries, precision and compliance are non-negotiable.

Every industry has unique labeling requirements. Beverage producers need labels that can withstand changes in moisture and temperature. Cosmetic brands must achieve flawless presentation when applying their labels to containers of various shapes. Pharmaceutical manufacturers face strict labeling regulations from regulators like the U.S. Food and Drug Administration (FDA).

A reliable industrial labeling machine ensures that every package meets those expectations while improving operational efficiency.

Labeling Machines for Beverage Packaging

The beverage industry depends on consistency, speed, and durability. Bottling lines can process hundreds of units per minute, leaving no room for labeling errors. A moisture-resistant industrial labeling machine ensures labels adhere cleanly, even in humid or cold environments.

Accutek’s labeling systems, like the APS line, are designed to handle high-speed beverage lines with minimal downtime. We use precision sensors and easy adjustment options to guarantee consistent label placement, even when bottle sizes or materials vary.

With accurate labeling, beverage brands can maintain their image and reduce material waste.

Labeling Solutions for the Cosmetic Industry

In cosmetics, it’s presentation, presentation, presentation. Consumers judge a product by how it looks before they even try it. A misaligned or bubbled label can damage your brand’s reputation. A customer will see it and think to themselves, “Well, apparently they can’t be bothered to make this look good. So whatever’s inside probably isn’t all that great either.”

That’s why manufacturers turn to automated packaging and labeling machines that deliver smooth, consistent application on every container. They can’t take the chance that the average customer will see their product as something subpar.

Accutek offers systems (like the APS134) capable of labeling complex shapes, from tapered lotion bottles to curved perfume containers. Advanced controls allow for fine-tuned alignment so every label looks seamless. The result is packaging that reflects your brand’s quality and sophistication.

Pharmaceutical Labeling: Accuracy Meets Compliance

Pharmaceutical packaging demands complete accuracy. Labels must display critical information—ingredients, lot numbers, expiration dates, and dosage instructions—without error. Failing to meet standards outlined by the FDA’s drug labeling regulations can result in fines, recalls, or worse.

A high-performance labeling …

The post appeared first on Accutek Packaging Machine Equipment.

Gifts Received

Labeling Machine has not received any gifts yet

© 2026 Created by XLFD.

Powered by

![]()

Comment Wall

You need to be a member of The Ludington Torch to add comments!

Join The Ludington Torch